By Agu Collins Agu

How should energy companies monitor and manage their oil and gas storage facilities?

No amount of investment in tank level monitoring makes sense unless you can be totally confident that the tank data you get is accurate and reliable.

If you don’t have accurate data, you’re doomed to a negative ROI. You won’t be able to make savvy decisions that reduce costs, increase revenues, boost sustainability, and maximize safety.

RELATED: APPLY: Unity Board free webinar holds 31st October

This Smart IoT-enabled Remote Tank Monitoring Solution enables energy companies to gain real-time insights into receipt, storage, and consumption patterns; pursue tank capacity optimization strategies with consistent and reliable data through:

Remote Access

No matter where your fuel tanks are located or moving, with the help of IoT technology and its advanced uses, it is easier to access those remotely

Advanced Analytics

The installed sensors on the oil and diesel tanks extract relevant data.

As soon as the user has access to the data and other relevant information related to the oil/diesel tanks, it simplifies the whole management. This further leads to better analysis of the data through advanced algorithms and generates result-based outcomes. Thereby, increasing productivity and enhanced decision-making for better business growth. Using IoT-enabled advanced analytics, the managers can make better decisions as required for their businesses and enhance their productivity at all angles.

Predictive Maintenance

It enables the business authorities to follow predictive maintenance, which helps them in identifying the asset flaws and exact conditions. With the help of this information, the authorities can predict scheduled maintenance and reduce operational and maintenance costs. It helps increase the overall profits of the business and ensures progress at an exponential rate.

Real-time Monitoring

The technology is an asset to various industries due to its real-time monitoring approach, which triggers notifications and SMSs in form of updates to the managers instantly. The technology thus provides real-time monitoring of the industrial assets that enable the managers to take necessary actions.

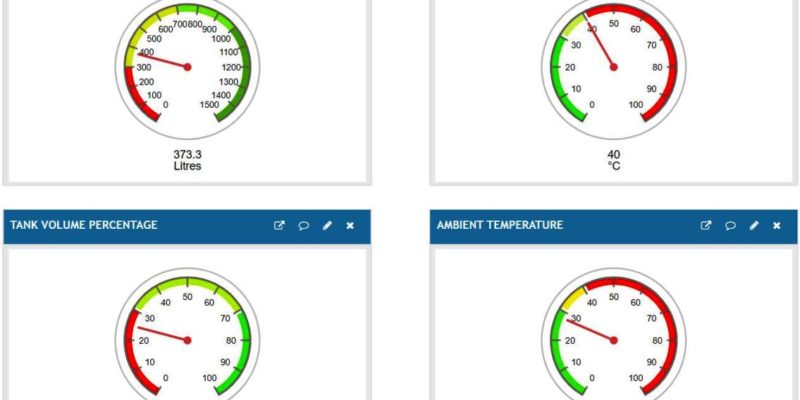

This solution creates visualization and enables users to remotely identify and track tank levels, temperature and utilization for a variety of liquids, including diesel, gas etc. and could also be used for monitoring silos etc.

Follow the link below to see live data stream from a tank at td4pai Hub, Kuje. FCT. NIGERIA.

https://thingspeak.com/channels/1774321

Agu, IoT Systems Expert/Electronic Product Design/Programmer, UnityBoard Co-Designer, is Director R&D, NITDA